A discussion about the AGV symposium paired with a look into the future

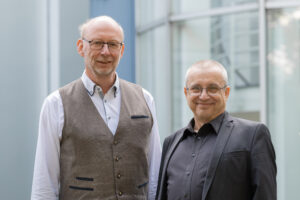

Every two years, the crème de la crème of driverless transport systems meet at the AGV symposium, initially in Duisburg, later in Hanover and now for the seventh time in Dortmund. Jan Kaulfuhs-Berger, President “elements of journalism”, spoke to the organisers of this event, Dr Günter Ullrich, Head of VDI Technical Committee 309, and Thomas Albrecht, Head of Automated Guided Vehicles at the Fraunhofer IML in Dortmund.

Jan Kaulfuhs-Berger: Günter Ullrich, driverless transport systems (AGV for short) have received a significant boost in recent years – we’ve talked about them before. However, the whole thing is anything but a new topic, as the history of the AGV symposium shows.

Günter Ullrich: That’s right, the AGV symposium has been taking place for many, many years. We started this event in 1991 at the University of Duisburg and have always focussed on the operators. We support them with a range of presentations and information.

There are many conferences. What is special about this one?

Günter Ullrich: The special thing about the conference is that we don’t have the manufacturers’ sales managers on stage, but that the operators’ project managers are there to talk about their experiences from real projects. That is the purpose of the AGV conference and what makes it so special. After being in Duisburg for a while, we then spent some time in Hanover and have now been in Dortmund at the Fraunhofer IML for many, many years …

… where the symposium is mainly organised by you, Thomas Albrecht.

Thomas Albrecht: Yes, this is our seventh time in Dortmund. The proven concept of the event has not changed much compared to previous events. What sometimes falls behind in communication, however, is that we always start the evening before the actual conference with a pre-event in a relaxed atmosphere. This is the best opportunity to make new contacts or renew old ones.

But there are one or two changes, aren’t there?

Thomas Albrecht: Yes, of course! The first real change in this event is that this time our new Institute Director, Prof Alice Kirchheim, will be welcoming us and giving the keynote speech. The topic has not changed: Innovations in intralogistics. This will be followed by the actual presentations. As already mentioned, these are users reporting on their own projects – i.e. logistics managers, operations managers and managing directors. They usually report on very new systems – including an AGV deployment in a hospital in Switzerland and a new system at Porsche in Zuffenhausen. And of course we have plenty of breaks between the presentations. Two dozen companies will be presenting themselves and their products, solutions and services. It’s a great place to start a conversation – and these conversations are an essential part of this very personal event.

Does the FTS conference cover a wide range of topics or does one main focus emerge from the presentations?

Thomas Albrecht: Well, this year, you could almost say that we have a small focus on retrofitting. In other words, the decision to introduce an AGV was made several years ago. However, these systems have now been retrofitted due to various circumstances.

We would not have combined retrofitting and AGVs in this way now.

Thomas Albrecht: But it is an issue, because the AGV – as the history of our conference shows – is anything but new. And why retrofit? Because components are no longer available, because the latest software may no longer run on old computers. So, there are various reasons why a user or operator may decide to have the system retrofitted, ideally by the original supplier. However, this also means that the operators were satisfied with the supplier and the system. So, we hear presentations about why the decision was made in favour of a retrofit and how it was carried out. This always takes place during ongoing operations, which then brings with it certain challenges in terms of implementation.

The common thread running through all AGV conferences is the panel discussion, Günter Ullrich.

Günter Ullrich: Yes, the panel discussion that I am moderating, if I may say so in all modesty. As always, a current topic will be examined from various angles and should once again deliver tangible results. This year’s topic is: “The future of AGV and AMR projects – opportunities, risks and recommendations”.

We understand this correctly: it is not about the future of AGVs and AMR, but about the future of AGV and AMR projects.

Günter Ullrich: This is indeed about AGV and AMR projects. And the question that arises is: How are the projects changing? We all know that they have changed in recent months and will continue to change. These changes naturally present opportunities, but also risks. We will discuss this. What will prevail and what recommendations can the panel give the viewers? Representatives from Bär Automation, MHP Management- und IT-Beratung, SSI Schäfer and, of course, Fraunhofer IML will be taking part. As you can see, the panel discussion will feature interesting representatives from various interest groups.

Thomas Albrecht: Yes, that will be really exciting. But I would like to say something else: it cannot be denied that the presentations we are hearing in Dortmund are more about the past and present, as they are about completed projects. When we look at our work here at the IML, it is primarily focussed on the future.

What drives you and your colleagues?

Thomas Albrecht: Well, the questions that concern us revolve around artificial intelligence (AI for short). This is also an issue for us, we can’t avoid it. The question is what AI can actually do, in which areas can it be used sensibly? We are currently investigating this in several research projects.

For example?

Thomas Allbrecht: What many people are doing, of course, is using AI in image processing. In logistics, this is obvious in the following fields of application: picking, packing, gripping and sorting, quality control, etc. When it comes to vehicles, for example, we have a current project with the ‘LoadRunner’. AI is also used there – although not exclusively. It also includes classic control and regulation technology. But when it comes to navigation, for example, AI is used there.

And the “EvoBot”, we suppose. If you can elaborate a little on this.

Thomas Albrecht: Yes, technically speaking, the “EvoBot” is based on an inverted pendulum …

… so not one that hangs down, but one that stands upright.

Thomas Albrecht: That’s right. This is of course much more demanding in terms of control technology. This vehicle can also drive very fast and balance itself, it can stand still and not tip over. But it can also pick up and drop off containers. It can also hold heavy boxes while an employee takes something out or puts something in. We have investigated various applications and have now started a project with an industrial partner, an enterprise lab. So far, the whole thing has had more of a prototype character. This is now being industrialised.

Very briefly, what are the advantages?

Thomas Albrecht: It is agile, fast and can also travel on uneven ground – in other words, it is not the classic AGV-compatible floor, as the guideline so nicely puts it.

Gentlemen, let’s look a little further into the future. What is in store for us in the area of AGVs?

Günter Ullrich. In my opinion, what lies ahead of us in the next three years can be divided into four points: Firstly, the regulations in the EU and the USA do not harmonise, but rather contradict each other to a certain extent. This needs to be harmonised. Secondly, the supplier markets are changing completely. The Asians, and the Chinese in particular, are currently forcing their way onto our market and offering very favourably priced vehicles and systems. And in the area of applications in the public sector, new questions and challenges are constantly arising.

The topic of AI is still missing.

Günter Ullrich: That’s right. We are moving away from the binary world and towards an AI-supported world in which we have operating modes with remote functions, for example. In other words, functions that can be carried out by a robot by a person sitting anywhere in the world. Previously, you had to ask yourself whether you could automate this – yes or no? Now you can go down the route of saying: I want to automate, but perhaps start with 30 per cent and want to be at 80 per cent in perhaps ten years’ time. The whole thing is AI-supported with a remote function – a learning system that will ultimately put you in a very good position.

And number four?

Günter Ullrich: Drones. You would have laughed about that a few years ago …

… and you too, I’m sure.

Günter Ullrich: Yes, I certainly do (laughs). But we are now seeing applications that make sense. For example, if I have an additional drone system, I have a redundant system, which gives me additional data security, but also increases the availability of the overall system.

Gentlemen, the topic remains with us and, in our opinion, is becoming more and more exciting every time. Thank you very much for the interview!

September 2024 – jak

This article was published first in “Technische Logistik” 09/24.